How to Increase Pipeline Safety within the Maritime Industry

SOLAS Compliant Safety Shields for Corrosive and High-Temperature Environments.

In the marine industry, where vessels and offshore platforms operate under extreme conditions, safety is key. From chemical tankers to research vessels, pipelines often carry hazardous or high-temperature media that pose serious risks to personnel and other equipment. One spray out or leak has the potential to cause catastrophic damage. Safety shields offer a cost-effective, reliable first line of defense and consolidate compliance with SOLAS (Safety of Life at Sea) regulations.

At Corrosion Resistant Products Ltd, we offer a comprehensive range of safety shields designed to meet the diverse needs of marine applications. Here’s a breakdown of our shield types and where they’re best used:

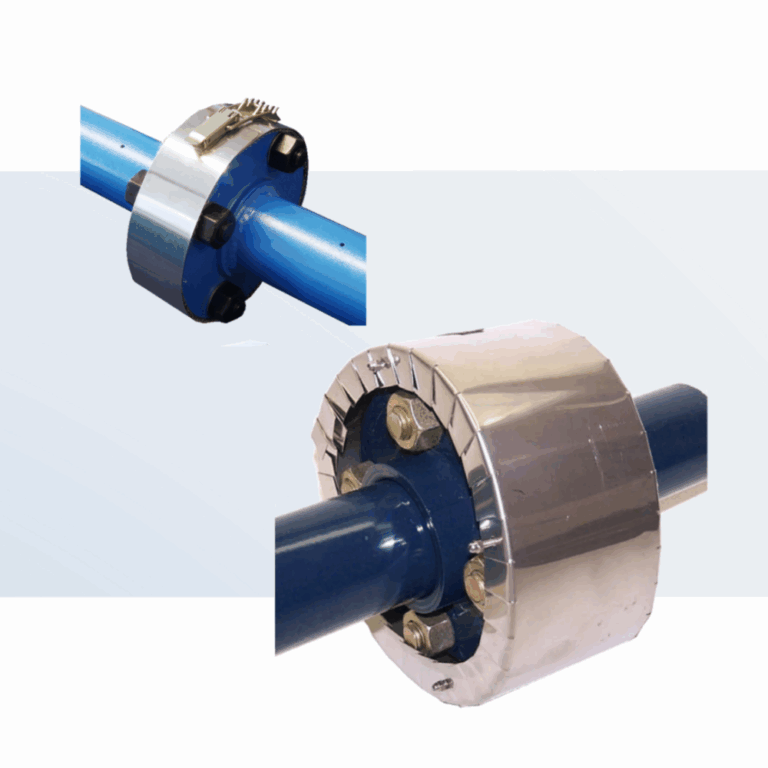

High Temperature Flange Shields

Features:

- Constructed from stainless steel.

- Operates up to 1,100°C / 2,012°F and 200 barg.

Applications:

- Hot oil systems in marine food processing.

- Steam lines and thermal transfer systems on vessels.

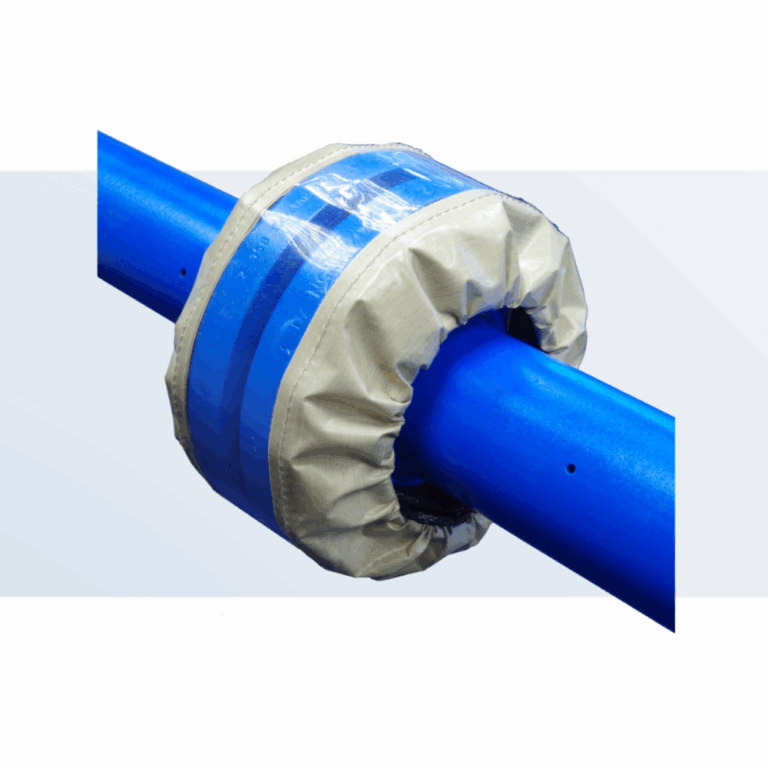

Clear Flange Shields

Features:

- Bag-like design with Velcro and PTFE-coated glass fibre cord ties.

- Crystal-clear Teflon® FEP window for safe and easy visual inspection.

- Withstands temperatures up to 200°C / 392°F.

- UV protected, rip-proof, and weather resistant.

Applications:

- Chemical handling systems on tankers.

- Desalination plants and marine research vessels.

- Any pipeline requiring regular inspection without shield removal.

Spray Guard Roll

Features:

- Made from chemical-resistant polypropylene.

- UV resistant and easy to cut to size.

- Secured with stainless steel self-tapping screws.

Applications:

- General-purpose leak deflection on deck or in engine rooms.

- Temporary shielding.

Why Use Safety Shields in Marine Environments?

- Compliance: Meets SOLAS safety standards.

- Protection: Shields personnel and equipment from spray-outs, leaks, and bursts.

- Durability: Built to withstand saltwater, UV exposure, and mechanical stress.

- Efficiency: Quick installation reduces downtime and maintenance costs.

Conclusion

Whether you’re operating a chemical tanker, a polar research vessel, or an offshore platform, CRP’s safety shields can play a key role in protecting your vessel and personnel. With options tailored to temperature, chemical resistance, and inspection needs, we help you maintain safety without compromising performance.