Project Spotlight: Designing a Robust Sampling System for Highly Corrosive Acids

We were tasked with designing a robust sampling system capable of handling highly corrosive acids. The challenge? Not only did the system need to collect the highly corrosive sample in a sealable bottle, but it also required precise dosing, and the cabinet had to be both mechanically strong and corrosion resistant.

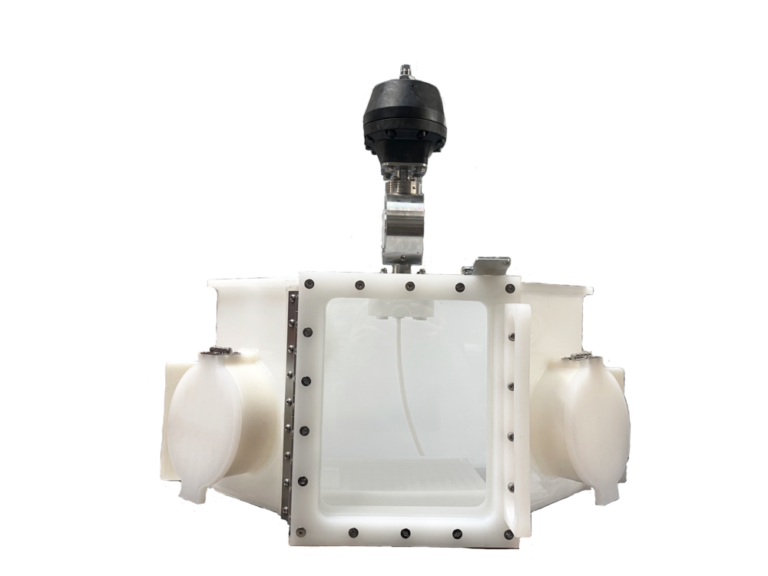

Andreas Papachristodoulou, design engineer, described the challenges of the project and how CRP’s PFA lined SD-IL 400 Pneumatically Actuated Sampling Valve C/W PVDF glove port cabinet was the best solution:

“To meet these demands, I opted for our high performance PFA-lined sampling valve controlled by a pneumatic actuator. PFA-lined valves are the preferred way to go for acid handling, and the pneumatic actuator, ensures accurate dosing every time. For the sealed bottle, I selected a GL45—our trusted go-to.

The cabinet posed a trickier challenge. During a call with the customer, our engineering team proposed a glove port cabinet made from polypropylene, complete with end caps to seal the ports when not in use. Polypropylene, being both strong and corrosion-resistant, seemed perfect. However, the customer expressed concerns that the acids might be too aggressive for polypropylene. In response, one of our engineers suggested PVDF, a material with superior mechanical and corrosion-resistant properties, albeit at a higher cost. In the end the customer’s requirements were met with precision and durability.”

At CRP it is our mission to solve problems on your plant, including designing and and producing custom products. to find out more about Sampling systems or our subcontract manufacturing follow the links.