Eliminating corrosion in the hydrogen industry.

Green hydrogen production is worldwide a growing industry, the UK alone for example has 11 new production projects that will invest around £400 million over the next 3 years, growing the UK’s green economy. The hydrogen is a clean alternative to methane and is set to reduce carbon emissions and aid countries in achieving net zero emissions. The EU aim to be carbon neutral by 2050.

and the hydrogen industry will play a significant role in achieving this. At CRP we are aiding the hydrogen production industry by providing our corrosion resistant, top-quality and high performance HiPerFlon* PTFE/PFA lined pipe and fittings.

The hydrogen industry needs long lasting and cost-effective solutions in order to shift global reliance on fossil fuels to green energy.

What is Hydrogen and How is it produced?

Hydrogen is an abundant chemical element but is very scarce in its gas form. Therefore, the gas must be produced artificially to provide sufficient quantities. It is non-toxic, colourless and odourless but importantly is highly combustible. It is used in ammonia production, as feedstock, power generation, fossil fuel refineries, steel production and in fuel.

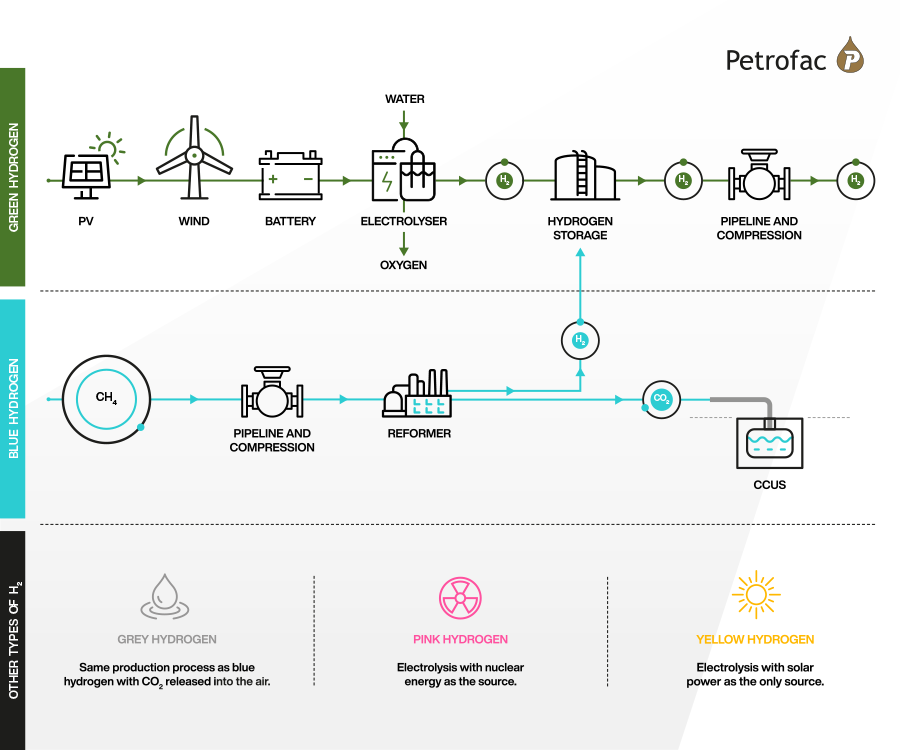

There are a variety of methods used to produce hydrogen, they are referred to using a colour system, green and blue are the cleanest.

93% of the world’s hydrogen is produced using grey (using natural gas) processes and major investment is being made into transforming these processes to a greener alternative. This presents steady growth in green hydrogen production. These projections however rely on cost effective and scalable infrastructure.

As many countries such as the UK have net zero goals the process of hydrogen production is shifting from grey energy to blue to green, as green and yellow hydrogen is the cleanest option with no carbon dioxide emissions and its only byproduct being water.